AVI Boston Turns To 3D Printing for Automotive Customization, Cutting Costs and Saving Time

AVI Boston seamlessly weaves technology into crafting personalized and bespoke automotive parts like dashboards, radar installations, door panels, and beyond. What puts them ahead of the curve is their expertise in integrating cutting-edge audio and visual systems, elevating both the car’s aesthetics and functionality. Their innovative approach is amplified by their use of 3D printing to manufacture end-use parts with BigRep’s G2 to bring their concepts to life.

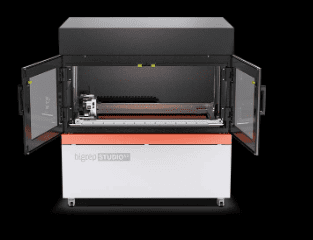

Having been in the automotive customization game for over seventeen years, AVI recently approached BigRep to purchase the STUDIO G2 – a large-format 3D printer.

"It's almost like having a full-time employee building a part."

“A big issue we were facing was that we didn’t have enough hands onboard. Finding good fabricator installers is really difficult and now we have a 3D printing machine that does that for us, it's almost like having a full-time employee building a part," said Safi Barqawi, the owner of AVI Boston.

What the STUDIO G2 Brought to the Table

“We can design everything specifically, just press print and we have the entire file on our computer. The cool thing is we have a scan of the door, the dashboard, the center console, design and build it even if the car is not here.” added Safi.

STUDIO G2 features that MOVED the

needle for AVI BOSTON

Large Build Volume

The STUDIO G2 boasts of a generous build volume of 1000 x 500 x 500 mm, 10 times that of standard desktop 3D printers. This enables AVI to create sizable quality end-use parts in a single print job, expanding the possibilities for customization.

Reduces Post Processing

Compatible with the STUDIO G2’s dual extrusion system, water-soluble support material BVOH is a revolutionary filament in post-processing. This ecologically friendly advanced material delivers support during print and massively reduces post-processing.

Dual Extrusion

The ability to print structures with two different materials without having to swap out filaments. The STUDIO G2 eliminates the need for filament changes and opens up possibilities for an uninterrupted seamless print without changing hands.

Digital Inventory

Produce on demand without added costs and uncertainty of keeping stock parts. Instead of stocking up on parts and running the risk of them going to waste, AVI could hit print as needed and create intricate, functional structures like dashboards, doors, center consoles, and cup holders.

How AVI Benefited From BigRep’s STUDIO G2

Works Around The Clock

Having the STUDIO G2 is like having an extra pair of hands in the garage that works without a pause, occasionally needing a bit of grease. “We get five orders, we just press print five times, go away for the weekend, and come back all five prints are ready for us Monday morning” says Safi. “We do a lot of magnetic kits for a specific vehicle and once we design it, we can print it as many times as we'd like without having to recreate the product itself.”

Complex Geometries And Fine Details Come Through

Car parts like custom interior panels and speaker covers need intricate designs that are time-consuming and particularly hard to achieve with traditional machining methods. “With the STUDIO G2, we’ve been designing these parts in-house and building clean structures for such intricate pieces. We would never be able to do that by hand. Getting down to that small of a detail is really hard. What would take days or weeks to get manufactured outside is done in a fraction of the time with the STUDIO.”

Cost Effective Solution

One of the perks of 3D printing in automotive customization is its ability to reduce production costs. With traditional manufacturing processes, tooling and molds are often used resulting in high costs. In comparison, when AVI switched to the STUDIO, it eliminated the need for expensive tooling resulting in reduced production costs, especially when it came to low-volume production and customization.

Intuitive User Interface

“The STUDIO G2 has been nothing but positive all the way around. The machine is extremely easy to use, it's very intuitive, if you want something, you just press print as many times as you want, and it’ll just keep printing it.” The STUDIO is equipped with an intuitive user interface that enables AVI to remotely load gcodes onto the system. The other functions supported by the machine are calibration of the print bed, stop and start operations, and monitoring systems in conjunction with BigRep’s CONNECT. “So, if there are three things that we do all the time, we have three presets on there and you just press print when you are ready for it. It's a very well thought out product backed up by a very good service team.” Safi elaborated.

The BIG Advantage

The conventional way to produce car parts has been highly manual. With the STUDIO, AVI could directly print end-use parts that cost way less and fit perfectly the first time which also helps them stay on top of project timelines. The compact design of the 3D printer was the icing on the cake that enabled AVI to host it right in their workshop. “One of the coolest things about the STUDIO G2 is that it’s sleek and allows us to be super-efficient with the space we have. This gave us the ability to design and print parts with a 3D printer in-house” concludes Safi.

Want to learn more about car customization empowered by additive manufacturing?

Register to watch the on-demand webinar, Digitizing Production of Custom Large-Format Automotive Parts.

Learn how digitizing this process drastically reduces production time and number of stages while saving money and material costs. Also hear from Jeremy Katz, owner of JK Automotive Designs, and see first hand how Katz embraced different technologies, allowing his team to offer more to their clients and continue exceeding expectations. Don't miss out, register for the webinar:

DIGITIZING PRODUCTION OF CUSTOM LARGE-FORMAT AUTOMOTIVE PARTS

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

About the author:

Copywriter

Natasha Mathew enjoys trying new things and one of them she’s currently obsessed with is 3D printing. Her passion for explaining complex concepts in simple terms and her knack for storytelling led her to be a writer. In her 7 years of experience, she has covered just about any topic under the sun. When she’s not carefully weighing her words, she’s reading, crafting, spinning, and adventuring. And when asked about herself, she writes in the third person.