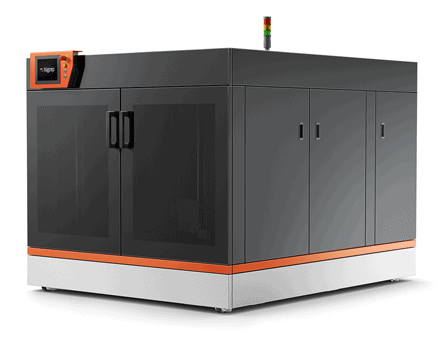

The BigRep PRO is an industrial large-format 3D Printer to support your company's development and production. Since the PRO launched in 2018, the BigRep R&D team has mainly focused on making this machine better by listening to what the customers wanted.

With an almost one cubic meter build volume, the BigRep PRO is a fully enclosed industrial 3D printer for producing full-scale, large parts, including functional prototypes, factory tooling, patterns and molds, and end-use parts.

In November 2021, we launched a newer and more powerful BigRep PRO, also known as the PRO.2.

Our focus? EASE-OF-USE. We built a large-format 3D printer that can be used by everyone.

This blog post lists 6 time factors about the BigRep PRO to better understand this 3D Printer's potential.

It took 12 seconds to remove the parts below from the bed by bending the SWITCHPLATE®

Ever had issues removing big 3D printed parts from your printer? Well, say no more!

Quoting Kerry Stevenson, Founder at Fabaloo:

“I can personally attest to slicing up my appendages on several occasions when wrestling a print stuck on a glass plate with a sharp chisel. Not fun at all.”

The SWITCHPLATE® is magnetic and easily snaps into place. Heat increases the adhesiveness of the SWITCHPLATE® surface, so your print stays fixed during printing but is easy to remove once cooled. For time-saving production, the SWITCHPLATE® can be swapped before cooling to free the printer to begin the next print.

Thanks to this feature, the effort to remove large parts from the bed is radically reduced. No need for scrapers, brims, or worrying about your appendages!

In 8 minutes, your BigRep PRO is automatically calibrated

We had a precise aim: make sure the first layer is ALWAYS right.

Why is the first layer so important?

Believe it or not, a not adequately calibrated first layer for single or dual extrusion is the leading cause of FFF 3D print failures for desktop and large-format 3D printers.

With the updated MXT® Controls, the brain of the BigRep PRO, calibrating won’t require manual actions and can not be wrong. The MXT® Controls use proprietary algorithms and surface-mapping to bypass manual print bed and extruder calibration, ensuring that the crucial first print layers are optimal every time.

Before a new gcode starts printing, the machine will run an autocalibration process, which takes around 8 minutes. In the first step, the extruder will map the printing bed and build a digital mesh. Secondly, the PRO will print a few lines on the bed; the sensors will map them to gather the necessary information, ensuring a perfect first layer with the Z calibration and a perfect XY calibration for dual extrusion.

To put things in perspective, manually calibrating a large format 3D printer can take up to 2 hours!!!

2 hours and you will be mastering our slicing software BigRep BLADE

BigRep BLADE is a free and easy-to-use slicing software allowing greater control of printing parameters on all BigRep large-format 3D printers. With BLADE presets, you can easily prepare your 3D printing files in just a few clicks. Features like auto-orient and auto-placement make BLADE simple to use.

Large-format 3D printing doesn't only mean big parts. With the BigRep PRO, you can also produce several smaller pieces using the "batch production" feature of BLADE.

This feature will ensure the parts are printed "sequentially," 3D printing one STL after another rather than printing all of them simultaneously. This process is only possible with large-format 3D Printers with an XYZ moving portal like the BigRep PRO and will save you up to 10% in printing time, depending on the geometries, in just one click! Software optimizations are great, aren't they?

If you want to discover more features about BigRep BLADE and how it has been optimized for large-format 3D printing, you can download BLADE for free and watch our basic and advanced training.

Also, if you are used to slicing files with Cura, BLADE will look much more familiar!

By slicing the above four manifolds sequentially instead of all together, we saved 5% printing time.

13 days! The longest print we have run on a BigRep PRO so far.

The BigRep PRO has been designed to 3D print as long as you need with its custom-built gantry engineered for high speed, fast acceleration, and accuracy. The robust frame eliminates vibrations during printing, assuring fast yet precise movement gliding the extruders along with a reinforced carriage system. Powered by Bosch servo motors with integrated encoders, the PRO calculates the real-time location of the print head to self-monitor for position accuracy. We call it the 2nd Generation Motion Portal.

In addition, the already-mentioned MXT® Controls orchestrates the harmonious coordination of all components and processes to ensure fast printing, accuracy, and repeatability. It employs proprietary algorithms that improve your gcode print file. The result is better quality, such as smoother surfaces from spline interpolation, higher accuracy from backlash compensation and vibration filtration, and overall consistent results.

That’s why our customers can 3D print 24/7, reliably.

Unfortunately, we can not show you the 13 days part because of an NDA, but we can show you how a six-and-a-half-days print of a prototype for a car bumper looks fresh out of a BigRep PRO!

For 2 weeks, your engineering materials are kept dry in the filament chamber

The PRO’s environmentally sealed filament chamber with a two-spool capacity ensures that all materials, including engineering-grade and water-soluble, remain dry in a consistent temperature and humidity-controlled environment. Even when powered off, the PRO’s airtight material storage ensures best-in-class quality and reliability.

In addition, we need to highlight that we give you a choice regarding the filament. The BigRep PRO is an open system, which means you can use third-party filaments.

BigRep offers original filaments with qualified BLADE profiles, including biopolymers, fiber-filled, engineering-grade, and water-soluble support materials, meaning you can start printing virtually any shape immediately. On the other hand, we know that some customers prefer to order their filament from different providers or make their own!

For example, our customer METSO Outotec uses a BigRep PRO in Brasil to manufacture large-scale sand casting patterns. Close to their facility, there is a filament provider able to support them with the material they need. METSO Outotec preferred to use locally produced material.

Why should we lock you in a closed system?

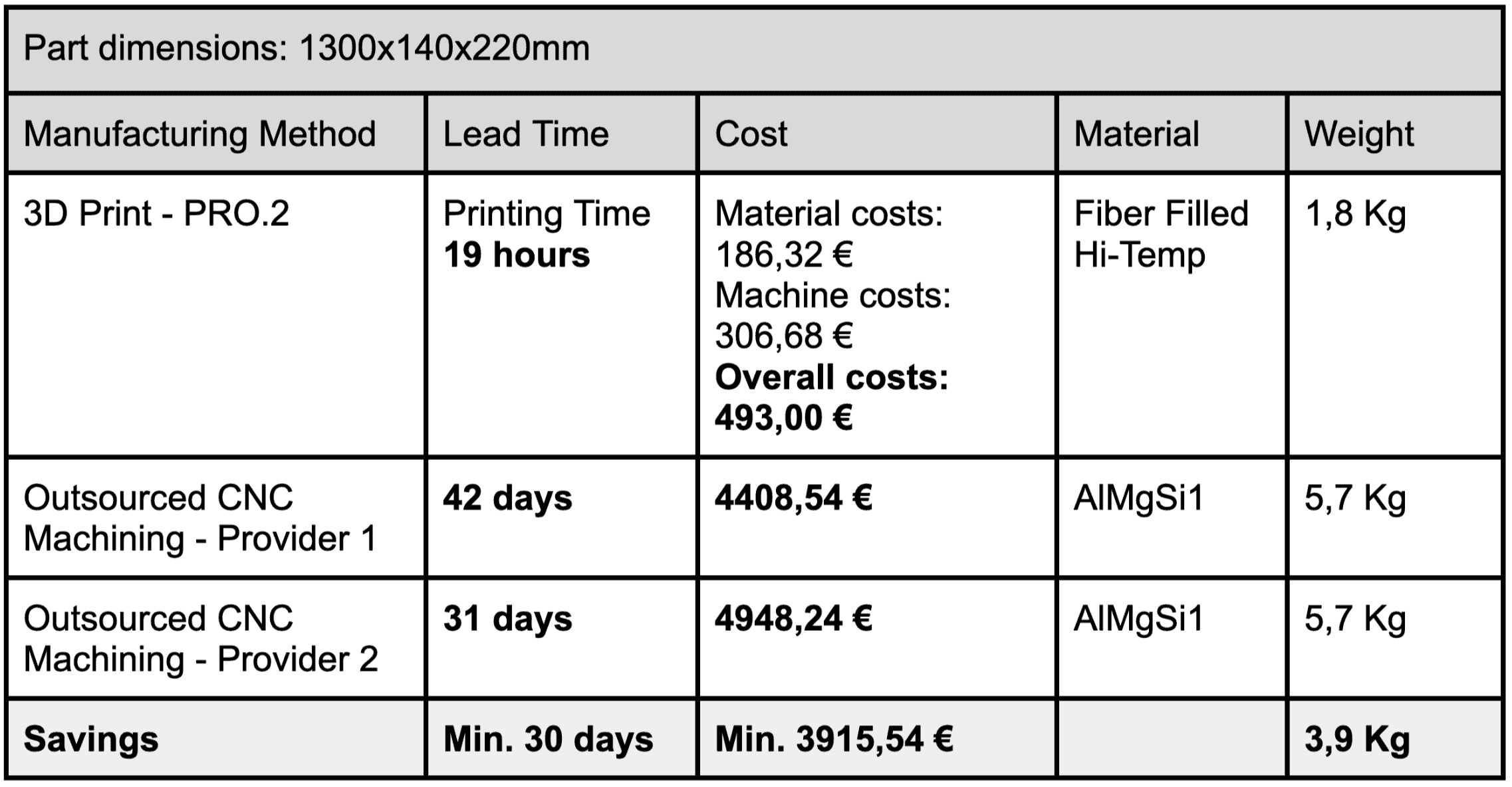

1 month shorter lead time than outsourced CNC machining

We 3D printed a large-format hand-held jig (see picture below) and compared the lead times with a couple of CNC machining shops in Germany.

The results are pretty interesting:

If you are interested in learning more about how 3D printing and CNC work together, download this ebook for free!