There are several factors to consider before purchasing a large format 3D printer. Since there isn't a 3D printer that will fit every single application that you may have, it is important to understand your application(s). When purchasing a large printer, you can imagine that the printer will take up quite a bit of space and will have electrical requirements. But it is also important to think about your part usage, the material requirements, software required, how the print will be supported and budget.

Let's jump in and review the top 6 considerations before purchasing a large-format 3D printer (like BigRep).

1. Application

The first and most basic question to ask yourself is “what do I want to 3D print and why?” Understanding this basic question first, will help you identify opportunities and where you can benefit most from a large-format 3D printer.

- If 3D printing prototypes, will they need to be function for form and fit checks or will they be more for design approval?

- If 3D printing tooling, where will it be used in for example the production line or for CMM inspection?

- If 3D printing end use parts, what environment will it be used in and what tolerances does it require?

For example, if you are just going to be 3D printing large parts for prototypes to show off to the marketing team or trade shows, then you can go with some basic materials, like PLA or PLX. If you need the prototype to simulate the end-use part, then you must compare systems that allow you to print in engineering grade materials (like BigRep). This is the same for additive manufacturing of end use parts or small series production runs, which often require higher-end engineering grade materials such as nylon and carbon fiber.

The second important to question in relation to application is “how big are the parts I want to 3D print?” A benefit of a large-format 3D printer is that you can print big parts or lots of smaller parts. This is one of the limitations of smaller printers in that you can never print big parts in one print, you’ll always have to piece them together after.

2. Materials

When you compare materials that you will print with, you should consider if you want your system to be a closed or open-source 3D printer. What’s the difference? Close systems require you to only use that printer’s material and locks you out of using 3rd party material. An open-source system allows you to use any material within the spec of the printer.

You might like the option of purchasing their materials from any supplier, others like to keep it simple and stick with the supplier that they purchased the equipment from.

There are manufacturers that supply material that you must use in their system and only their materials, which can be good and bad. It is good because the material properties are the same every single time, it's bad because it can be costly, and you may be limited to only those materials.

3. Space and Environment

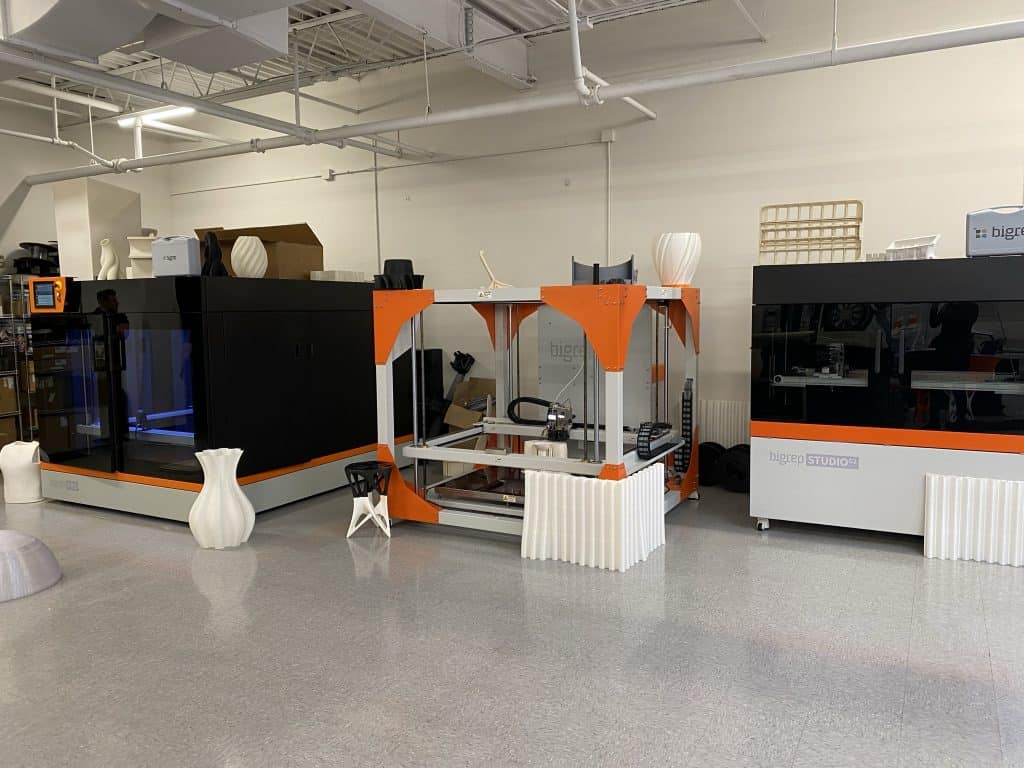

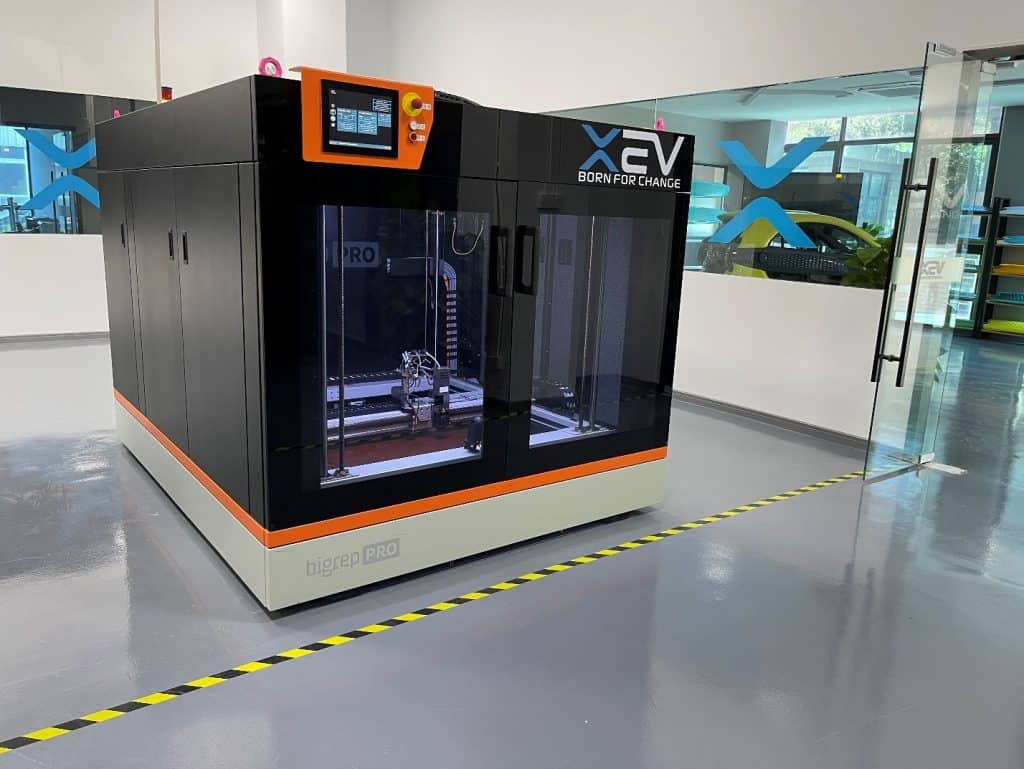

Large-format 3D printing means big 3D printers. The obvious question is, “do you have the space for it?” BigRep’s largest 3D printer is x 1950 y 2500 z 2105 mm ( x 77 y 98 z 70 inches) and our smaller one is x 1715 y 1170 z 1765 mm (x 67 y 46 z 69 inches). BigRep 3D printers work great on the shop floor, in labs and offices, and more.

Depending on the environment where the printer will sit, you might want to consider whether you will require a climate-controlled room. Will humidity be a factor in the space? Are there particles floating around from other equipment? What material will I mainly be printing with? These factors can influence the outcome of the print. If the 3D printer is in a lab that is enclosed, then you can probably get away with an open frame system.

Lastly, keep in mind that most large-format 3D printers require high electrical output, this can be crucial factor to think about when deciding where to put it.

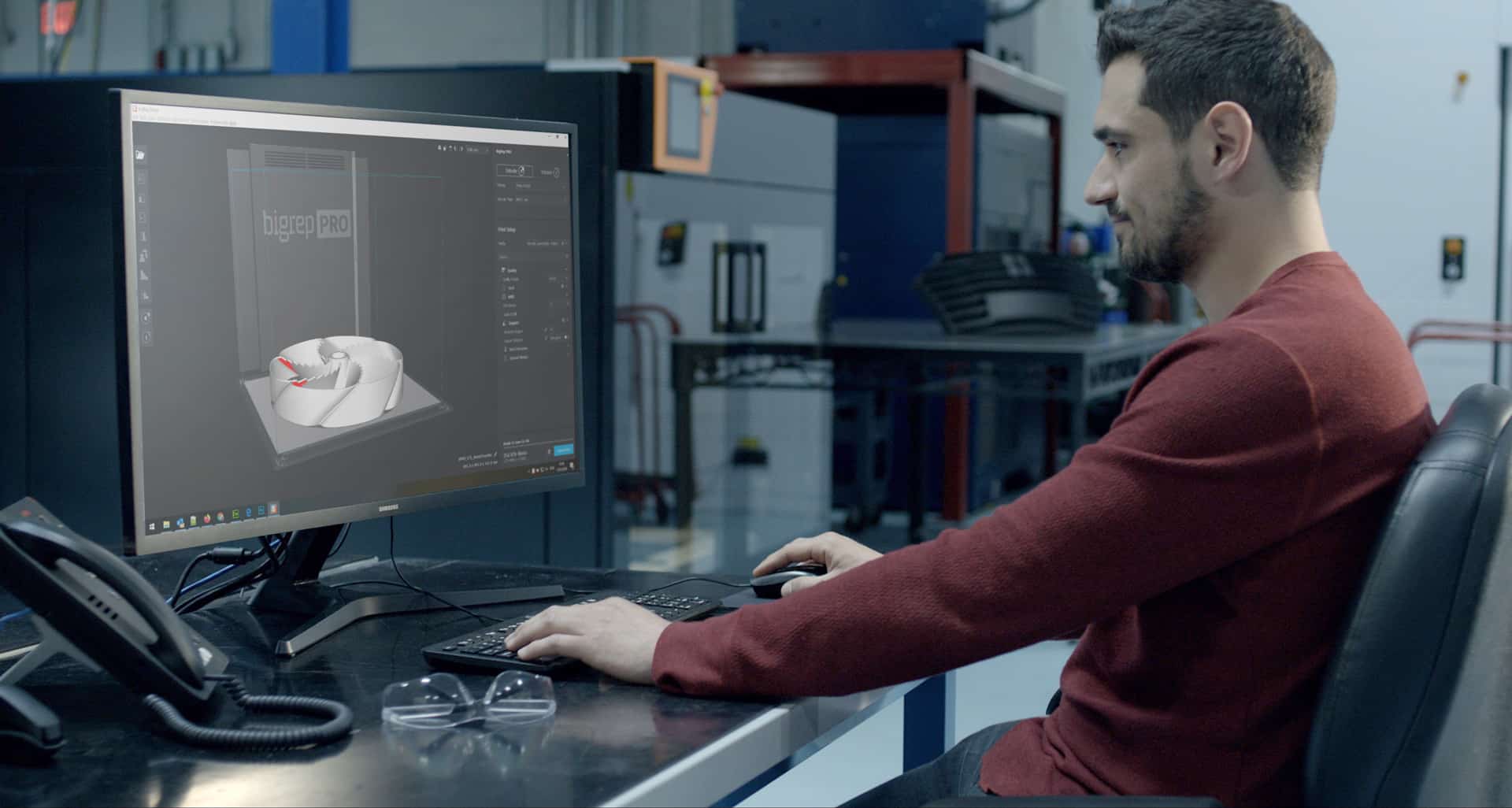

4. Software

Almost every equipment manufacture has its own software that will set up the part to be built and sliced but some 3D printing companies are also open source and allow you to choose any slicing software. This comes with both advantages and disadvantages. Maybe you already have a software you are familiar with and want to continue using it. The software that comes with the printer, like a BigRep 3D printer is pre-loaded with profiles for materials and settings for the printer, making it very user friendly to start prints quickly.

Things to consider when evaluating the software…

- Who will be running the machine?

- Have they used 3D printers before or are they brand new?

Some systems require a higher level of expertise to run, and others are pretty much plug and play. Let the manufacturer install and train you regardless of what 3D printer you end up investing in. With large parts often comes warpage, not just with 3D printing but with almost any manufacturing method. Understanding how to set up the build to reduce or eliminate warping, work with your local support team for the best settings, part orientation, and material for the parts you are trying to print. Lean on their expertise, the right company will give you the right service you deserve.

5. Local Support

Having local support is often an invaluable asset to any 3D printing company. Ask for references, talk to customers who are using the printers and understand their experience working with the company and if the level of service makes or exceeds your expectations. When you invest in an industrial large-format 3D printer, you expect the level of support to match the price tag of the printer.

It is important to select a printer that wants you to succeed and will help you get you up and running quickly. BigRep provides local support through our global and regional headquarters (Berlin, Boston, USA and Singapore), as well as a network of reseller partners around the globe.

6. Budget

Investing into a large-format 3D printer requires more than just what is mentioned above, but one of the most important questions to ask is, “what is my budget?” Try to be open when it comes to purchasing, because if you only have a certain dollar amount to spend but then that purchase a lower cost option that becomes more of a headache than an investment, was it worth it?

There are ways you can also be creative, for instance, the 3D printer within your budget for equipment funds and the installation, training, materials and shipping in another fund. There are leasing options as well. Talk with the experts and really analyze some parts you plan to print and what that would mean for your ROI. Often BigRep customers realize a positive return on investment more quickly than they expected.

Conclusion

Large-format 3D printers can help with so many applications from prototypes to end-use parts. When starting your search for a large-format 3D printer, the best advice is to talk to those who are already doing it. Ask for their recommendations and then evaluate those solutions and make sure it’s a good fit for your application and goals.