How the Aix-Marseille Université aerospace facility’s technology-enhanced degree program is made possible with BigRep’s large-format additive manufacturing systems.

On Marseille’s busy south-France coast, Aix-Marseille Université, one of the largest universities in France with 8,000 staff and 80,000 students, has developed a unique accredited degree programs in aerospace engineering and maintenance by combining two novel technologies: large-format additive manufacturing and virtual reality.

Xavier Bonnardel is a doctor of aeronautics, a professor at the University of Aix-Marseille, as well as founder and director of Aix-Marseille’s technical aeronautical training school, POLYAERO. Bonnardel created POLYAERO in 2008 and, in 2016, helped establish its aeronautical formation center in the luscious Gap Tallard airfield – a 2500 m2 specialized facility for the technologically advanced POLYAERO programs. Students from all over the world enroll in the exclusive program every year, drawn by the modern tools it uses to provide a unique hands-on education, a BigRep industrial 3D printer among them.

In 1994, as France’s shipping regulations around aircraft maintenance made it difficult for universities to meet state criteria, Bonnardel took on the challenge of developing an effective university program to meet the new restrictions. In a partnership with Airbus, Bonnardel and Aix-Marseille developed their program which later became nationally recognized, making POLYAERO the first school in Europe with a part 66 C regulation-compliant bachelor program in aircraft maintenance.

Beyond simply meeting state regulations, Bonnardel and POLYAERO are no strangers to the rapidly evolving demands in education as schools strive to remain aligned with modern industries like aviation and their ever-changing technologies. The school has partnered closely with notable aerospace companies from around the world including Airbus, Dassault, and Safran to ensure they’re always at the forefront of innovation in aerospace. It’s with these close partnerships that POLYAERO has created their present exclusive program that leverages modern technology to give students unmatched hands-on experience, making them incredibly valuable to POLYAERO’s industrial partners.

POLYAERO functions with apprenticeship-style programs – not unlike the German “Duale Ausbildung” vocational training – operating in a cooperative system with leading international aerospace companies. By working with industrial giants like Airbus and Dassault, students rotate every two months between studying at POLYAERO’s Gap Tallard campus and working for their industrial employer. Positions in the programs are strictly limited to the amount of student interns POLYAERO’s industrial partners can handle, meaning at any given time POLYAERO has only about 100 students from approximately 1,000 annual applicants.

Technology-Assisted Learning in Aerospace

Trials in Virtual Reality

As a university institution, POLYAERO and Aix-Marseille simply don’t have the budget for a hangar full of the modern aircrafts that students will be working with after graduation. But without hands-on experience students are ill-prepared to enter the workforce, forcing aerospace companies to expand their training and onboarding to get new entrants up to speed. Bonnardel decided that modern technology and some simple program logistics offered a path around these limitations and, expanding on his existing 25-year relationship with Airbus, began implementing modern technology into the learning process to create a virtual reality assisted learning program.

Airbus invested in the program early on, providing POLYAERO with digital mockups of their H175 helicopter to jump start their virtual aeronautic collection. They also helped to develop the program logistics and the use of its associated technologies. In fact, Airbus was excited enough about the program to place two highly qualified Airbus employees at POLYAERO’s facilities who still work out of the Gap Tallard campus today. In turn the school continues to develop and manage the program, constantly investing in facilities to support their modern technology. Due to its high technological integration, the campus maintains a variety of technology-learning facilities: 3D labs and simulation rooms like the “Virtual Reality Cave,” a dedicated space for students to safely use the virtual reality systems with two massive projected screens that allow instructors to follow their students’ performance.

Unfortunately, the first attempt at the program didn’t satisfy POLYAERO. Students received detailed learning into the practices and processes of aeronautical maintenance but didn’t quite get the hands-on experience that Bonnardel and Airbus were looking for the program to provide.

“We began to work with virtual reality, but we realized that it wasn’t very good - it was too much like a video game, not realistic enough. But Airbus wanted to development this technology and we worked together to do it.”

Xavier Bonnardel, Founder and Director, POLYAERO

That’s when POLYAERO connected with BigRep’s French reseller, Neofab, to acquire an industrial 3D printer large enough to meet their needs as they delved into the program’s next stage. “We needed to put more physics into Virtual Reality – the mass of objects to be moved, geometrical encumbrances such as firewalls, etcetera. And thus, to transform Virtual Reality into Mixed Reality.”

Additive Manufacturing for Mixed Reality Learning

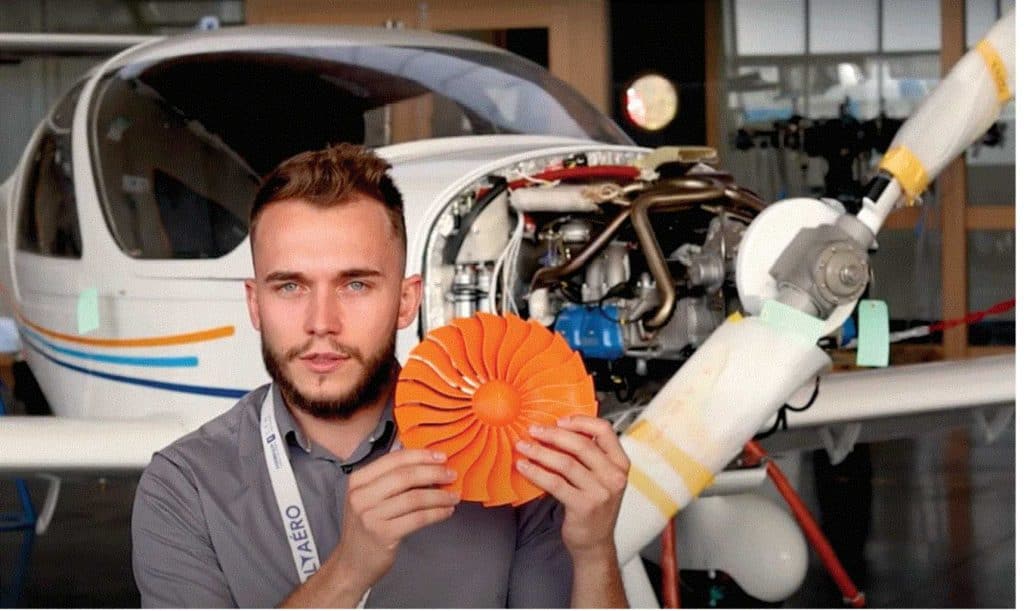

Having already acquired the tools of a virtual reality training system, POLYAERO leveraged additive manufacturing to double down on their technological solution. If virtual reality couldn’t deliver a genuine experience, they needed to mix the limitless scenarios and aircra s offered by virtual reality with physical experiences. Using their BigRep 3D printer, POLYAERO introduced Mixed Reality, to balance the benefits of virtual reality and physical, 3D printed mockup parts for an ideal training solution.

Before acquiring their 3D printer, POLYAERO tried to have students create mockup parts out of cardboard to act as stand ins for genuine aerospace parts. While these hand-made mockup parts did offer better physical stimulus to learn, the parts were often flimsy, dimensionally inaccurate, and incredibly time consuming to create – cutting into student’s valuable learning time.

POLYAERO decided that to have a Mixed Reality program that truly enables virtual learning, the parts students are working with must be as close to the real thing as possible. Here is where BigRep’s large-format additive manufacturing systems have shined.

With their part copies printed on a BigRep 3D printer, POLYAERO’s students save an abundance of time that would otherwise be wasted creating mockups, work with copies that match a real part’s dimensions, and are sturdily manufactured with BigRep’s affordable PLA filament. Because of the parts’ added strength, POLYAERO’s students are even able to include weights that further serve the realistic illusion they’ve created.

As added value, the students working with POLYAERO are gaining valuable experience with 3D printing technology and CAD software – an important tool in the modern aerospace industry. “with this generation of students we didn’t have any problem,” Bonnardel said when asked how students have been getting along with the integration of this new technology. “For them there is no problem.”

Virtual Modeling with 3D Scanning

Though the majority of POLYAERO’s fleet is digital, there are a few aircrafts of their own in the Gap Tallard campus’ 700 m2 hangar: two Dolphin SA365 helicopters and a Lark 3 SA316 from Airbus, a TB10 and MCR4S, a KOMPRESS class 6 ULM and five UAVs. All these aircrafts were provided free of charge by POLYAERO’s industrial aerospace partners.

POLYAERO adds to their ever-growing database of virtual aircrafts by using 3D scanning to create digital copies of every part on the aircrafts they routinely acquire on a temporary basis. Students get hands-on with aircrafts in real life, tearing them down to individual parts and reverse engineering them. By doing this they not only help to build their school’s virtual database, but also garner their own experience.

“It’s like making a painting,” Bonnardel said as he explained how students easily scan airplanes and helicopters before treating the files with specialized so ware to create a final, perfect digital copy of the aircraft and all its parts. “We can reproduce or improve the aircraft, if you want.”

Hands on Prototyping

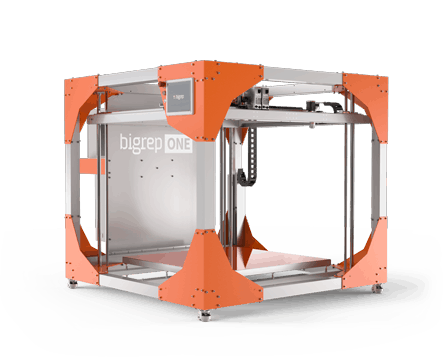

Students aren’t just learning how to work with and maintain existing aircraft parts. POLYAERO has installed a wind tunnel so that students can design, print, and test their own part prototypes. By running parts through the wind tunnel students can perform an aerodynamic analysis, collecting the data they need to understand their part’s effectiveness. When using prototypes printed on their one-cubic-meter BigRep 3D printer, students can easily test, verify, and reiterate designs – just like industry professionals.

“For students it’s just a job of engineers. It’s practical engineering because they not only know theory but practice,” said Bonnardel. “It was unthinkable five years ago.”

Growing use of plastic AM in Aerospace

While creating their prototypes, POLYAERO’s students are gaining valuable experience with one of the most prolific, and iconic, additive manufacturing applications in the aerospace industry. Industrial giants have cut up to 90% of prototyping costs by integrating additive manufacturing into their workflows. Adapting these workflows has brought processes in-house to eliminate outsourcing expenses, unlocked unlimited iterations and dramatically reduced each iteration’s lead time to create an affordable prototyping process that gets companies’ innovations to market faster. By familiarizing students with this common process, POLYAERO is ensuring their success in a common aerospace engineering workflow that only continues to grow.

But 3D printing is quickly finding use in other areas of the aerospace industry too, with some of POLYAERO’s partners like Airbus creating affordable logistical aids – like shipping cases for delicate aerospace equipment – that can traditionally cost up to $15,000 on-demand with BigRep’s additive manufacturing systems.

Conclusion

Other methods of production simply couldn’t meet POLYAERO’s needs for realism and flexibility. While they could have outsourced their mixed reality mockup parts, the costs would have been prohibitive. Given the variety of parts that POLYAERO works with, the initial investment in their own industrial 3D printer was returned quickly compared to other possible acquisition strategies. By bringing a BigRep large-format 3D printer in-house, POLYAERO has created a flexible system that not only supplies the strong, realistic parts they need for their mixed reality programs, but also adds a valuable industrial tool to their state-of-the-art facilities. With it, they’re enriching students’ educations with one of the aerospace industry’s most disruptive technologies.

POLYAERO has observed such positive results from their mixed reality bachelor programs that they have decided to take the next step and create a Master of Aerospace Engineering program based upon the same principle. Bonnardel says that the program will carry on learnings taken from their previous experience to create a program that focuses more on the impact that industry 4.0 will have on aerospace engineering than other programs that exist today.

Applying an additive manufacturing solution to surpass the shortcomings of virtual reality assisted learning is just one of the many creative ways industrial additive manufacturing is finding unique, previously unexplored applications in advanced industries. POLYAERO’s impressive mixed reality program serves to show that when talented engineers work to redevelop traditional processes from their foundation, large-format 3D printing and BigRep additive manufacturing solutions result in previously unimaginable efficiencies and reinventions.

1M³ BUILD VOLUME. BIG POSSIBILITIES. SMALL PRICE.

The BigRep ONE is an affordable entry into large-format 3D printing. With proven dependability to work around the clock, the ONE brings your designs to life in full-scale.

1M³ BUILD VOLUME. BIG POSSIBILITIES. SMALL PRICE.

The BigRep ONE is an affordable entry into large-format 3D printing. With proven dependability to work around the clock, the ONE brings your designs to life in full-scale.